Environmental data

For transparency and comparability, we have published our key environmental data since our environmental reporting began in 2008. The data originates from Elopak’s internal reporting system, Footprinter, collated from production, administration and sales units worldwide.

Our environmental data shows the development of Elopak’s environmental impact each year, as prescribed in the Greenhouse Gas (GHG) Protocol, including the updated revisions of the GHG Protocol Scope 2 Guidance (2015). Our 2020 data has been audited and verified partly by SGS and partly by Anthesis Consulting Group.

How we report

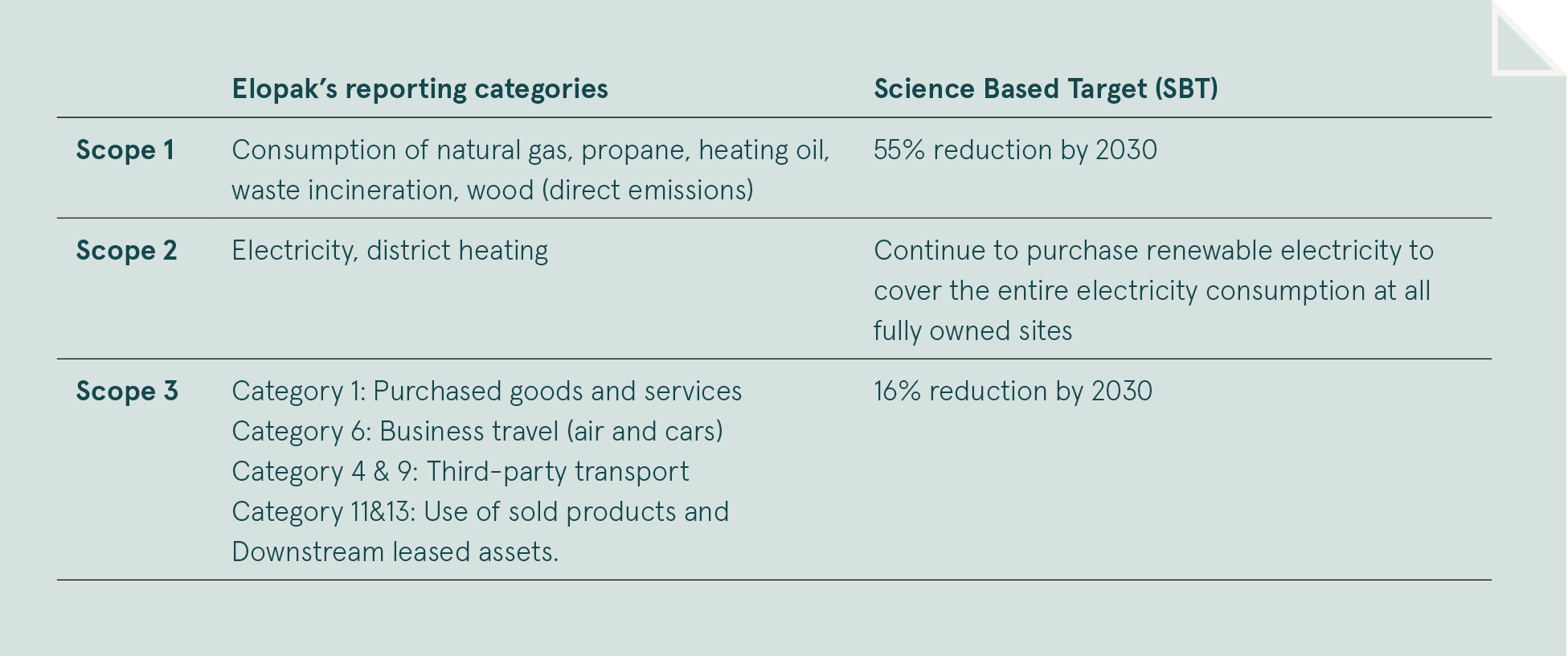

For our reporting, we abide by the Greenhouse Gas Protocol, a widely used standard for corporate environmental reporting. Elopak reports according to the ‘operational control’ consolidation approach, which covers all Elopak’s market units; and converting, roll-fed, coating and filling machine plants worldwide. Joint ventures are excluded. Elopak’s greenhouse gas data is reported in both CO₂ equivalents (CO₂e) and in the separate greenhouse gases. According to the GHG Protocol, a company shall divide its emissions into three scopes. These scopes are described in the figure below.

Emission factor updates

For 2020 reporting, all electricity emission factors (scope 2), were updated according to the latest 2020 International Energy Agency’s (IEA) database, known as “CO₂ Emissions from Fuel Combustion.” All site fuels (Scope 1), district heating (Scope 2) and business travel and transportation (Scope 3) emission factors were also updated according to the latest 2020 DEFRA (UK Department for Environment, Food & Rural Affairs) emission factors. By updating all emission factors annually, we are more in line with market realities and emission factor developments that have occurred since we first began reporting in 2008.

Science Based Targets

Elopak has committed to cut greenhouse gas emissions in line with the strictest criteria set by the Science Based Targets (SBT) initiative. Elopak has committed to cut Scope 1 emissions by 55% by 2030, to continue to purchase renewable electricity for the entire consumption at all Elopak fully owned sites, and to cut Scope 3 emissions by 16% by 2030. Elopak purchases renewable electricity through certificates, but even though the energy is renewable, there is a small CO2e emission factor linked to the renewable electricity certificates that Elopak purchases for Europe. These residual emissions in Scope 2 are included in Elopak’s Scope 1 target of 55% emission reduction by 2030.

Renewable electricity

Elopak utilizes the market-based allocation method for our Scope 2 accounting. In 2020, Elopak utilized Guarantees of Origin (GOs) to cover electricity consumption of our production and administrative facilities in Europe. For North America (Canada and USA), Elopak utilized a similar system, Green-e certified Renewable Energy Certificates (RECs). GOs and RECs are systems to trace the source of electricity produced. The purchase is based on actual electricity consumption at various Elopak units within Europe and North America in 2020. The emission factor used for the European GOs is given in the EPD from the energy company in Norway and is 0,0068 (kg CO₂e/kWh), and the RECs have an emission factor of zero.

The European Energy Certificate System (EECS) is the official European system for Renewable Energy Certificates (RECs) that was created to enable cooperation within renewable energy across borders. When the GO is used by a consumer, it is cancelled in the system to prevent double counting. More renewable energy demand leads to more investment in renewable energy and less greenhouse gas emissions. Every country participating in the energy certificate system has a central organization which oversees the national markets for GOs. In addition, the entire European system is overseen by the Association of Issuing Bodies. This ensures the credibility of the energy certificate system.

According to new RE100 criteria, the electricity consumed must be sourced within the same marked as it is produced. Most countries in Europe are included in the European single market. But, Elopak has two production plants, respectively in Russia and Ukraine, that are by definition outside the European single market. To adapt to the new RE100 criteria, Elopak will from 2021 onwards source I-RECS from Russian wind and solar PV to cover the electricity consumption from the Elopak production plant in Russia. No renewable energy certificate system is in place in Ukraine yet so Elopak will source GO’s from wind power from Poland in 2021. This will be done until Ukraine has established an energy certificate system and can provide I-RECs.

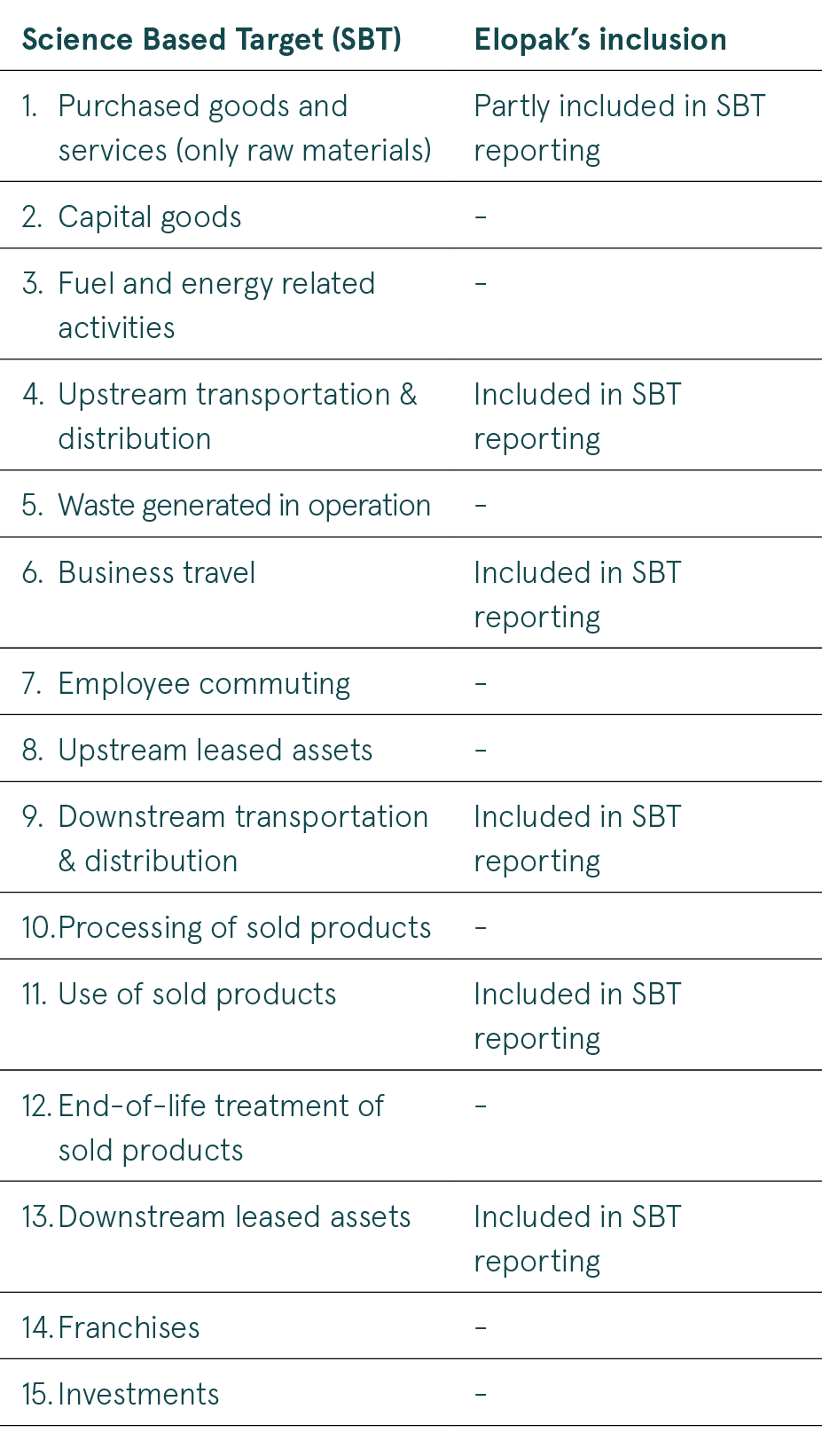

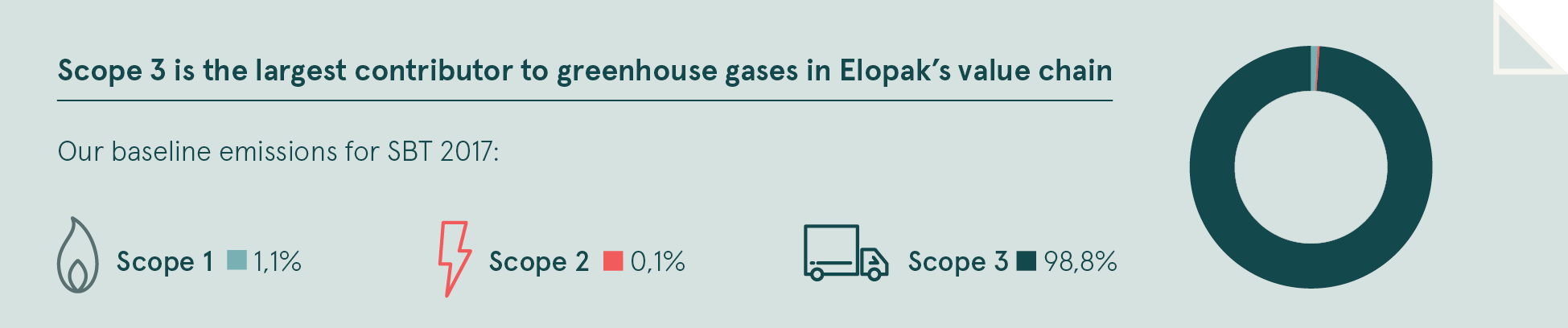

Scope 3 evaluations

In the process of setting internal emission targets for scope 3 in line with the SBT, we calculated and evaluated the emissions related to each of the Scope 3 categories. The criteria for selection of categories in scope 3 is that the chosen categories must cover at least two thirds of the total Scope 3 emissions. The table shows all categories in scope 3 and which ones are included in Elopak’s reporting. From the GHG emission calculations for the three scopes it is clear that scope 3 is the biggest contributor to GHG emissions in Elopak, accounting for almost 99% of the total GHG emissions.

Business travel

Elopak reports on emissions from business travel, both from flights and cars, by gathering data from all Elopak units through different portals. Due to the implementation of a new business travel management system, Elopak has improved the emission reporting from business travel flights the past years.

Some Elopak units are still reporting business travel manually in the internal reporting system, Footprinter. All data, from the new system and Footprinter, is compiled and calculated to get information on the total emissions related to business travel in Elopak. The emissions reported related to scope 3, category 6, business travel, for 2020 have been third party verified by SGS in 2021.

Transport

Elopak reports on emissions related to third-party transport. This reporting includes transport of all goods from suppliers’ gates via Elopak, to customers’ gates. All data is gathered, whether the transportation is purchased and handled by Elopak, or by our suppliers or customers.

The third-party transport is split into inbound, internal and outbound transport. Inbound and internal transport includes transport of purchased raw materials and semi-finished products. Outbound transport includes all shipment of manufactured products to customers. In estimating transport emissions, we have used a tonne-kilometer approach, as it is a straightforward and consistent method. Furthermore, the input required for this approach is more easily available than the input required for the vehicle-kilometer approach. With the former, we do not need to have full control over the loading of goods. This approach will most likely give us an overestimate of transport emissions, and thus is a valid conservative approach.

The emissions reported for 2020 related to scope 3 (category 4 and 9), upstream and downstream transportation and distribution (under Elopak’s operational control), have been third party verified by SGS.

Raw materials and cartons

To calculate carbon footprint of our products, we use internal calculations, which have been verified by a third party. We use an internal tool called “DEEP – Dynamic Elopak Environmental Performance” (version 9.0), which is a cradle-to-gate calculation that considers all emissions connected to the production of all raw materials, as well as Elopak’s own operations including final conversion, and all transportation up to the delivery at Elopak’s customers’ gate. The scope covers Elopak’s operation in Europe, and in 2019 we also developed DEEP for North America.

The methodology is in line with the ISO standards for Life Cycle Assessments (ISO 14040 and 14044). The Product Category Rules (PCR) for beverage cartons are followed where relevant to the carbon footprint calculation methodology (PCR Beverage Cartons 2011:04 Version 1.0, developed in accordance with ISO 14025:2006.

- Primary data is used for Elopak’s own operations and the production of some raw materials.

- Internal production data is taken from Elopak’s reporting tool, “Footprinter” (2020 data),

- Purchase of renewable energy certificates.

- Internal transport data is calculated based on reporting from Elopak’s units (2020 data).

- Suppliers’ primary data is used for key raw materials.

- Secondary data is sourced from LCA databases where this is relevant, such as EcoInvent, and studies for some of the raw materials, such as PlasticsEurope and the European Aluminium Association, as specified in the beverage carton PCR.

The emissions reported related to scope 3 category 1, purchased goods and services (raw materials), for 2020 have been carried out by Anthesis Consulting Group in 2021.

Filling machines in operation

Elopak is producing filling machines and is both selling and leasing these machines to customers. The use of sold and leased filling machines at customer site is a part of Elopak’s scope 3 emissions, and is included in the SBT reporting. In order to calculate the emissions related to sold and leased filling machines, Elopak started with mapping all filling machines ever sold and leased. Then the emissions were calculated per machine, starting with summarizing the operation and cleaning consumption and applying emission factors. An estimated operation time for all the filling machines was assumed. For leased machines, consumptions and emissions are calculated for one year, and for machines sold the emissions are calculated for 20 years.

IEA per-country electricity consumption factors are applied according to the country of the customer. Factors for chemicals and transport are taken from Ecoinvent 3.4. Another key presumption is that current-year electricity factors are applied to the lifetime electricity consumption. i.e. no provision is made to estimate future reduction in grid electricity emissions.

The emissions reported related to scope 3 category 11 and 13, use of sold products and downstream leased assets (filling machines), for 2020 have been carried out by Anthesis Consulting Group in 2021.

Carbon neutral company and packaging

The carbon neutral company certification compensates for the emissions related to the manufacturing process, transport and business travel. This certification is in accordance with the PAS2060 standard. Carbon neutral packaging extends the scope of emissions to include all the emissions associated with the cartons (raw material production, waste and onward distribution). Carbon neutral packaging is certified according to The CarbonNeutral Protocol. All calculations are verified by an independent third-party, Anthesis Consulting Group. Company emissions has been additionally verified by South Pole upon issuing the carbon neutral certificate. Packaging emissions has been additionally verified by Natural Capital Partners.

For 2020, Elopak has supported three projects for our carbon neutral company certification. The projects are verified according to international standards used in the voluntary offset market, respectively VCS (Kenya agriculture and Isangi forest convervation project) and CDM (Clean Development Mechanism under the Kyoto Protocol – Landfill gas project Mexico). Certificates are issued by South Pole.

The projects supported for carbon neutral packaging in 2020 were also verified according to the international standards used in the voluntary offset market, respectively Verified Carbon Standard (VCS – Rimba Raya), Gold Standard (Cookstoves) and CDM (Clean Development Mechanism under the Kyoto Protocol – Wind power). The mangrove planting project is an additional project not creating carbon offsets. Certificates are issued by Natural Capital Partners.